When it comes to working with steel, there’s a dynamic duo of terms that often confound folks: fabrication and machining. These two processes are the powerhouses of the steel industry, but are they the same thing? The answer may surprise you. In this section, we’re going to roll up our sleeves, don our steel-toed boots, and delve into the world of fabrication.

Table of Contents

ToggleWhat is Steel Fabrication?

First things first, let’s get our definitions straight. Steel fabrication is essentially the art of shaping and assembling steel components to create something functional and, dare I say, beautiful. It’s like building a puzzle, but instead of cardboard pieces, you’re working with sheets, beams, and rods of steel.

The Fabrication Process

Now, what makes steel fabrication such a versatile player in the game? It all boils down to the processes involved. Imagine a steel sheet that needs to become part of a towering skyscraper or a sturdy bridge. Fabrication steps in like a magician with its bag of tricks:

Cutting

The first trick in the bag is cutting. This can be done through various methods, including plasma cutting, laser cutting, or good old-fashioned shearing. Each technique has its unique advantages, whether it’s precision, speed, or cost-effectiveness.

Bending

Once the steel is cut to the right size and shape, it’s time to bend it like Beckham (or in this case, like a seasoned fabricator). Bending machines help create curves, angles, and folds, turning flat steel into complex forms.

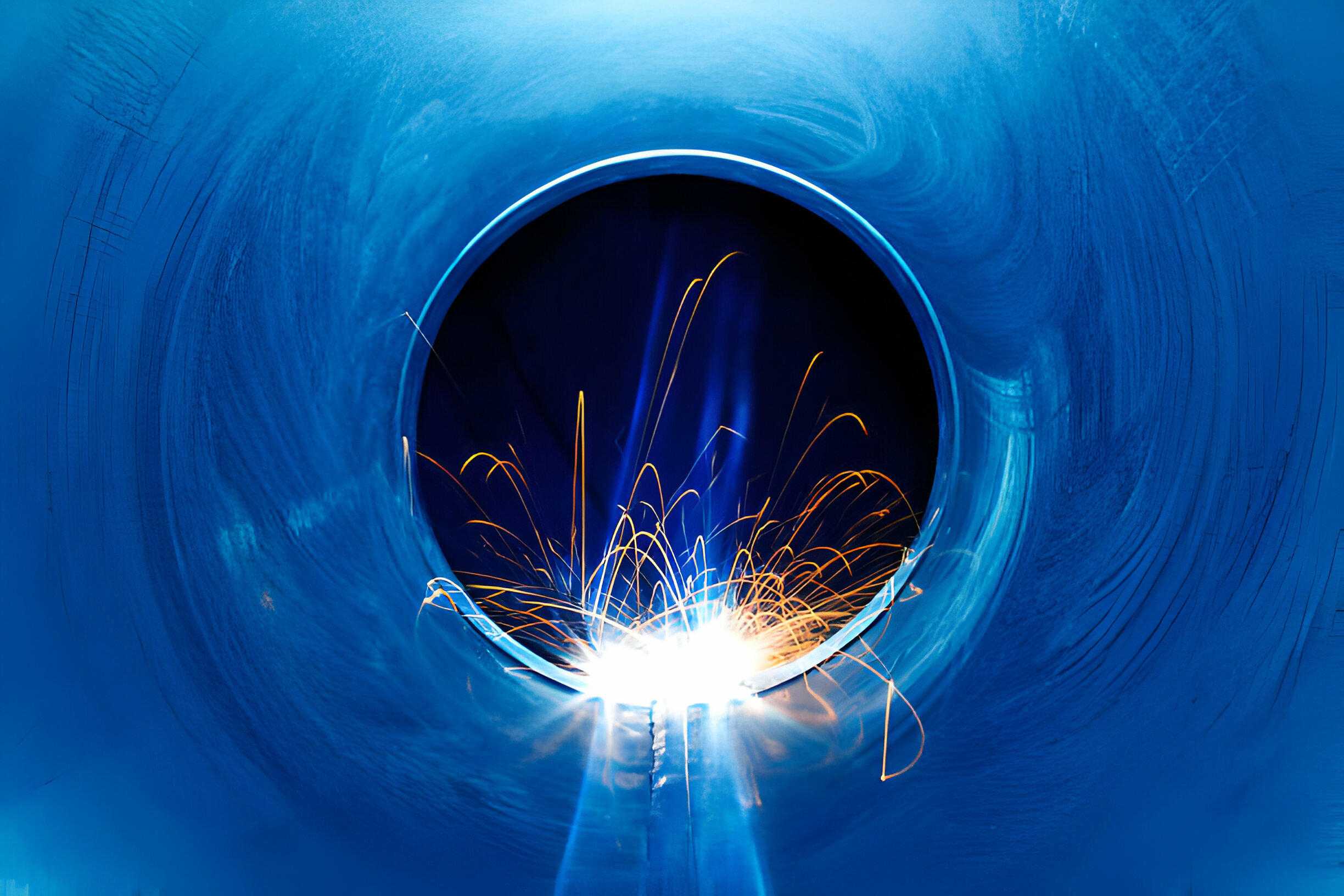

Welding

Now, here comes the pièce de résistance – welding. This process fuses steel components together, creating a solid and sturdy structure. Welding can make or break a fabrication project, as the strength and durability of the final product depend on the welds.

Assembling

Last but not least, assembling is where all the pieces come together. Bolts, rivets, and screws may be used to secure various components in their rightful places. It’s like putting together a massive, three-dimensional jigsaw puzzle, but with a bit more elbow grease.

Types of Steel Used

Ah, but not all steel is created equal. The type of steel used in fabrication can vary depending on the project’s requirements. Common varieties include carbon steel, stainless steel, and alloy steel, each chosen for its unique properties and suitability for specific applications.

So, in a nutshell, steel fabrication is all about turning plain steel into remarkable structures or components, and it’s a process that has a lot more versatility than you might initially think.

Delving into Machining

Now that we’ve got a firm grip on steel fabrication, let’s shift our focus to the enigmatic world of machining. If fabrication is the sculptor, then machining is the fine-tuner, working its magic to create precision parts that would make even the fussiest engineer nod in approval.

What is Machining?

Machining, my friends, is the process of refining and shaping existing pieces of steel to achieve a level of precision and finish that would make a Swiss watchmaker green with envy. While fabrication builds structures, machining hones the tiny details that can make or break a project.

The Machining Processes

To understand machining, it’s essential to grasp the fundamental processes that make it tick. Think of these processes as the secret ingredients in a chef’s signature dish:

Turning

Imagine a lathe, a trusty machine that spins a piece of steel while a cutting tool slices away excess material. This turning process transforms a rough piece of steel into a perfectly cylindrical component. It’s a bit like watching a sculptor turn a shapeless block of marble into a work of art.

Milling

Next up is milling, which uses rotary cutters to remove material from a workpiece. This process can create flat surfaces, slots, and intricate designs. Think of it as a steel pancake griddle, but instead of flipping pancakes, it’s shaping steel into complex forms.

Drilling

And then there’s drilling, which, as the name suggests, is all about creating holes. Whether it’s tiny holes for bolts or massive ones for pipelines, drilling is the go-to process. It’s like a precision drill bit dancing through the steel, creating openings with surgical precision.

Machining Tools and Equipment

Machining wouldn’t be the maestro it is without its array of specialized tools and equipment. These tools are like the brushes in an artist’s toolkit, each serving a specific purpose:

- CNC Machines: These computer-controlled marvels are the heart of modern machining. They can perform intricate operations with unrivaled precision.

- Cutting Tools: Think of these as the paintbrushes of the machining world. End mills, drills, and inserts are among the essential tools.

- Lathes: As mentioned earlier, lathes spin the workpiece, allowing precise cutting. They come in various sizes and configurations.

- Grinders: For achieving that smooth, polished finish, grinders are the go-to. They refine surfaces to a mirror-like shine.

Now, you might be wondering, how does all this machining differ from our trusty friend, fabrication? Well, it all comes down to the nature of the processes and their intended outcomes. Fabrication creates structures, while machining takes existing materials and perfects them with meticulous detail.

Machining is the realm of precision, where tolerances are measured in micrometers, and the surface finish is as smooth as a baby’s skin. It’s the final touch, the refined elegance, the cherry on top of the engineering cake.

Key Differences Between Fabrication and Machining

Now that we’ve had a taste of both fabrication and machining, it’s time to put on our detective hats and uncover the key differences between these two heavyweights in the steel industry. Spoiler alert: they may look similar from a distance, but up close, they’re as different as night and day.

Material Alteration

Fabrication’s Metamorphosis

Imagine you have a sheet of steel, and you need it to become the skeleton of a massive skyscraper. Fabrication steps in like a master tailor, cutting, bending, and welding that steel into the desired shape. It’s like taking a plain canvas and transforming it into a magnificent painting.

Fabrication is all about altering the form and structure of steel. It’s about turning raw materials into something entirely different, much like a caterpillar becoming a butterfly. This process involves changing the size, shape, and structure of the steel components to fit the project’s needs.

Machining’s Fine-Tuning

Now, shift your focus to machining. Picture a precision instrument, where every millimeter matters. Machining takes existing steel and refines it with surgical precision. It’s like an artist adding intricate details to a masterpiece.

Machining doesn’t alter the fundamental structure or shape of the material. Instead, it focuses on making precise cuts, creating intricate features, and achieving exceptional surface finishes. Think of it as a sculptor chiseling away to reveal the hidden beauty within a block of marble.

Tolerance and Precision

Fabrication’s Margin of Error

In the world of fabrication, there’s a bit more wiggle room. Tolerances in fabrication are typically measured in fractions of an inch or millimeters. This means that while it’s precise, there’s a bit of flexibility, like a well-tailored suit that allows you to move comfortably.

The tolerances in fabrication are sufficient for many applications, such as building structures, bridges, and even heavy machinery. However, it may not be suitable for components requiring micro-level precision.

Machining’s Surgical Precision

Now, let’s switch gears to machining, where precision reigns supreme. Machining tolerances can be mind-bogglingly small, often measured in micrometers or even smaller. It’s akin to a surgeon’s precision during a delicate procedure.

Machining can achieve unparalleled accuracy, making it the go-to choice for components where every fraction of a millimeter matters. Industries like aerospace, medical devices, and high-tech engineering rely on machining to create parts that fit together with Swiss-watch precision.

Cost Factors

Fabrication’s Cost-Effectiveness

When it comes to cost, fabrication often has the upper hand, especially in larger projects. Fabrication processes can be more cost-effective for creating extensive structures like buildings, bridges, or industrial facilities. It allows for the efficient use of materials and can handle substantial workloads.

Machining’s Price of Precision

On the flip side, machining tends to be pricier. The precision achieved in machining comes at a cost, both in terms of time and resources. The need for specialized equipment, skilled operators, and meticulous planning can drive up the expenses.

Machining shines when the project demands utmost precision and surface finish. It’s an investment in quality, suitable for components where even the tiniest deviation could spell disaster.

Applications and Industries

Now that we’ve dissected the distinctions between fabrication and machining, it’s time to explore where these two titans of steel craftsmanship find their respective homes in the world of industries and applications.

Fabrication Applications

Building a Better World

Fabrication, with its knack for shaping steel into large-scale structures, plays a vital role in industries that quite literally build our world. Here’s where you’re likely to spot the handiwork of fabrication:

- Construction: From the towering skyscrapers that touch the clouds to the bridges that span mighty rivers, construction relies heavily on steel fabrication. Structural components like beams, columns, and trusses are crafted through fabrication.

- Infrastructure: Roads, railways, and airports owe much of their strength and durability to fabricated steel structures. Think of the frameworks supporting highway signs, airport terminals, and railway platforms.

- Manufacturing: In the world of manufacturing, fabrication is the go-to process for creating everything from industrial machinery to assembly line structures. It’s the backbone of manufacturing facilities worldwide.

- Oil and Gas: In the energy sector, fabrication is essential for constructing oil rigs, pipelines, and storage tanks. These structures withstand extreme conditions and ensure a steady supply of energy resources.

- Mining: Fabricated steel plays a crucial role in the mining industry, from the extraction of raw materials to the transportation and processing of minerals.

Fabrication is the backbone of large-scale projects, offering the versatility needed to create structures that can withstand the test of time.

Machining Applications

Precision Matters

Machining, with its unparalleled precision and attention to detail, finds its calling in industries where perfection is not just a preference, but a necessity. Here’s where machining takes center stage:

- Aerospace: When it comes to aircraft and spacecraft, precision is paramount. Machining creates components like turbine blades, engine parts, and critical control surfaces.

- Medical Devices: Medical equipment requires precision down to the micrometer. Machining is used to craft intricate components for devices like surgical instruments, implants, and diagnostic equipment.

- Automotive: From the engine to the transmission, machining produces vital components that ensure the performance, safety, and efficiency of vehicles.

- Electronics: The world of electronics relies on precision machining for creating components like circuit board components and connectors.

- High-Tech Engineering: Industries involved in high-tech engineering, such as optics and robotics, turn to machining for creating specialized components that demand the utmost accuracy.

In these industries, even the slightest deviation can have significant consequences. Machining is the guardian of precision, ensuring that every component meets exacting standards. If you are looking for Structural Steel Fabrication in Sydney then look no further the Steel Fabricators Sydney.

Pros and Cons

Now that we’ve explored the domains where fabrication and machining shine, let’s take a moment to weigh the pros and cons of each process. Like any superhero, they each have their strengths and weaknesses.

Advantages of Fabrication

1. Customization

Fabrication offers a high degree of customization. It can adapt to various project requirements and create unique structures or components tailored to specific needs.

2. Scalability

It’s the go-to choice for large-scale projects. Fabrication can handle the construction of massive structures efficiently and cost-effectively.

3. Versatility

Fabrication is incredibly versatile, accommodating a wide range of materials and designs. It’s like the Swiss Army knife of the steel world.

Advantages of Machining

1. Precision

Machining is the paragon of precision. It can achieve tolerances that are simply unattainable through fabrication, making it ideal for high-precision components.

2. Material Refinement

Machining can refine materials to achieve specific properties, enhancing strength, durability, and surface finish.

3. High-Quality Finish

When aesthetics and surface finish matter, machining delivers a level of refinement that’s second to none.

Limitations

Limitations of Fabrication

- Limited Precision: Fabrication processes have tolerances that may not meet the requirements of ultra-precise components.

- Material Waste: It can generate more material waste compared to machining, especially for intricate designs.

- Size Constraints: Fabrication may have limitations when it comes to creating extremely small or intricate parts.

Limitations of Machining

- Cost: The precision achieved in machining comes at a cost, making it a more expensive option, especially for larger projects.

- Complexity: Setting up and programming machining processes can be complex and time-consuming.

- Material Removal Rates: For bulk material removal, machining may not be the most efficient choice.

So, there you have it, the intricacies of where fabrication and machining shine, along with their respective pros and cons.

In the vast landscape of the steel industry, fabrication and machining stand as two distinct titans, each with its unique set of skills and strengths. Fabrication is the sculptor, crafting grand structures and components with versatility and cost-effectiveness. Machining is the precision artist, refining steel with unmatched accuracy, perfect for applications where precision is paramount.

The key differences between these two processes come down to material alteration, tolerance, precision, and cost. Fabrication transforms raw materials into new forms, while machining perfects existing materials with surgical precision. Fabrication tolerances offer flexibility, making it suitable for a wide range of projects, while machining pushes the boundaries of precision.

In terms of cost, fabrication often has the upper hand for larger projects, whereas machining’s precision comes at a premium. However, both processes have their rightful place in the steel industry, serving industries and applications that demand their unique capabilities.

Remember, these two aren’t rivals; they’re partners in the grand symphony of steel craftsmanship. Fabrication and machining often complement each other within a single project, with fabrication creating the foundation and machining adding the finishing touches.

So, whether you’re marveling at the towering skyscrapers that dominate city skylines or admiring the precision of a state-of-the-art medical device, know that both fabrication and machining have played a significant role in bringing these creations to life.

In the end, the question of whether fabrication is the same as machining is answered with a resounding “no.” Each process has its distinct identity and purpose, and together, they form the dynamic duo that keeps the steel industry moving forward.

As we wrap up this exploration, remember that the next time you encounter a steel structure or component, you’ll have a deeper appreciation for the craftsmanship and precision that went into creating it, whether through fabrication, machining, or a harmonious blend of both. For information visit: https://www.industry.gov.au/publications/australias-steel-manufacturing-and-fabricating-markets.

FAQs

Are fabrication and machining the same thing?

Not at all. Fabrication involves shaping and assembling steel to create structures and components, while machining refines existing steel with precision tools. They are distinct processes with different objectives.

Which is more cost-effective, fabrication, or machining?

The cost-effectiveness depends on the project's requirements. Fabrication is often more cost-effective for larger structures, while machining is ideal for precision components where accuracy is paramount.

Can fabrication and machining be used together?

Absolutely! These processes often complement each other within a single project. Fabrication creates the initial structure, and machining refines specific components to meet precise requirements.

What industries commonly use steel fabrication?

Industries like construction, infrastructure development, manufacturing, oil and gas, and mining rely on steel fabrication for creating structural components and large-scale projects.

Where is machining predominantly used?

Machining finds its niche in industries such as aerospace, medical device manufacturing, automotive, electronics, and high-tech engineering, where high-precision components are essential.